What if you could accurately detect engine problems in just seconds without disassembling a single component? This sounds like the purview of a superhero or clairvoyant, but nearly anyone can do it, no cape or special powers required.

Engine Polygraph is an advanced computerized diagnostic tool that can quickly determine the overall health of an internal combustion engine, as well as identify between 10 and 12 different mechanical issues from misfires and bad fuel injectors, to worn camshaft lobes and even broken valve springs, serious issues that can be prohibitively expensive to correct if not addressed immediately.

Appealing to fleet customers, rebuilders, automotive repair shops, dealerships and others, “This technology works on any engine, whether it’s gas, diesel, CNG… as long as it’s producing a piston pulse, we are able to see what’s going on,” explained Doug Strock, president of Predictive Fleet Technologies, Inc.

Two Inputs, Copious Data

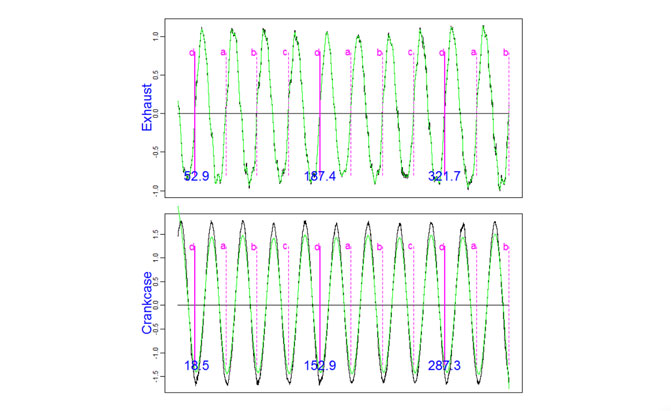

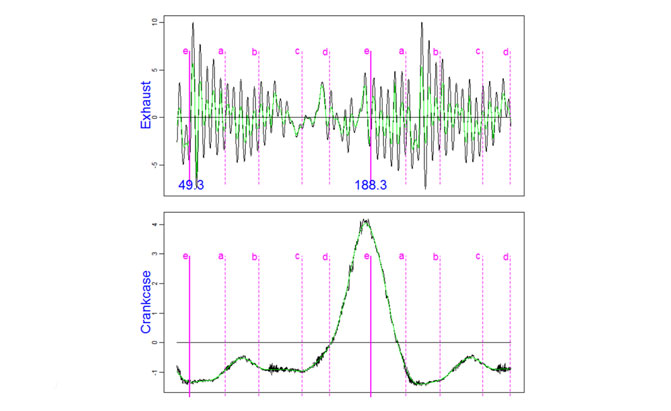

Surprisingly, to determine what’s going on deep inside an engine without, you know, ripping most of it apart, this system gathers data from just two sensors. One clips to the exhaust outlet while another plugs snugly into the oil dipstick tube. They measure pressure fluctuations produced while the engine is running, things that can reveal a mountain of information.

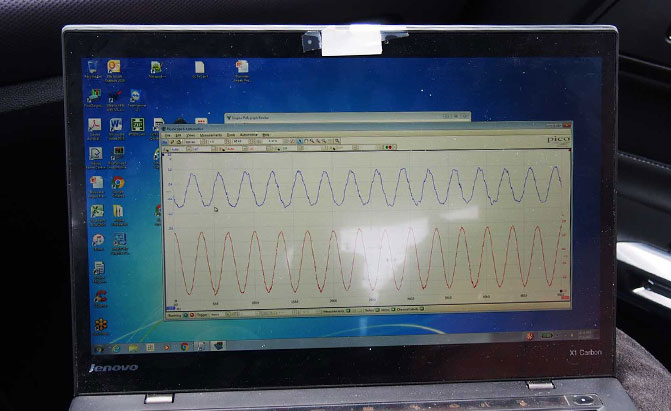

These instruments attach to something known as a PicoScope, which interacts with Engine Polygraph software running on a computer, helping turn raw data into readable graphs and ultimately an overall rating for the powerplant being evaluated.

The total score is given as a number, where one is the best and nine represents a worst-case-yet-still-running scenario. All told, the testing process takes about five minutes, including the time required to connect both sensors. Obviously, that’s a lot faster than pulling a cylinder head or dropping the oil pan.

SEE ALSO: The Million-Mile Toyota Tundra is in Shockingly Good Condition

Parsing all that data, Strock explained, “The software is what we’ve come up with to take the mystery out of that.” It’s how Engine Polygraph can detect so many different issues from just two input sources. For instance, during a misfire, unburned fuel exits the cylinder where it ignites in the catalyst, creating a later-than-expected power pulse. Poorly seated valves produce a high-pitched squeal, worn camshaft lobes result in a regular, high-frequency waveform, while undesirable metal-on-metal contact is evinced by vibration. Amazingly, all this and more can be derived from simply measuring pressure fluctuations.

Additionally, Strock said, “We detect volumetric efficiency,” which indicates how much carbon is built up inside an engine, an increasingly important issue as more automakers switch to direct fuel injection.

X-Ray Vision

Hooking Engine Polygraph up to a factory-fresh 2017 Ford Mustang EcoBoost revealed everything was working properly, with its 2.3-liter turbocharged four-cylinder receiving a perfect score of one. The graphs plotting sensor data had smooth, even waveforms, corresponding to ideal operation. But what else should you expect from a car with fewer than 500 miles on the clock?

Still, “A brand-new engine does not mean a perfect engine,” said Strock. Showroom-fresh vehicles aren’t broken in, there are always manufacturing variations in play and, of course, automakers do ship bad batches of powerplants from time to time.

In comparison, Strock showed test results for a diesel-powered Dodge Sprinter commercial van with nearly 240,000 miles on the clock and major under-hood issues. The graphs are a total mess with wildly unbalanced waveforms. Accordingly, Engine Polygraph was able to detect something awry with cylinder No. 5, though the test was performed too late to sidestep a what turned out to be a costly repair. Vindicating these findings, upon teardown, a hole was actually found in that corresponding piston.

The system’s ability to detect problems like this is revolutionary. Mike Colburn, director of sales at Predictive Fleet Technologies and something of a fuel-systems expert said it’s “the best invention I’ve ever seen,” likening it to an MRI doctors would use to non-invasively look inside the human body.

“When you start the car it is in a state of decay,” Colburn stated, “The real question is, how do you stop the decay?” With Engine Polygraph, it’s possible to determine exactly how well a vehicle is performing, and take necessary preventative steps to keep in in good working order.

Target Customers

Problems in modern vehicles often manifest as an enigmatic check-engine light but, “There’s no OBD code that’s going to show you head-gasket integrity,” said Strock. Oftentimes these warning lamps are merely the symptom of an underlying issue, not the cause. But Engine Polygraph “can really get you to a root state much quicker,” he said, allowing you to correct an issue before it becomes catastrophic, like what happened to that poor Sprinter.

This technology should appeal to independent shops, used equipment resellers and even dealerships to help them make repairs faster and save money. But Strock added they’re getting attention from an unexpected customer base.

“Where we have interest right now is [on] the warranty side,” he said, “The people that are doing engine warranties.” They need to ensure powerplants are in good enough condition to cover with a guarantee and they have to make sure regular maintenance is being performed. Engine Polygraph can help in both areas to monitor the overall health of a powerplant.

SEE ALSO: 10 Expert Detailing Tips on Keeping Your Car Looking New

What About Automakers?

Other potential customers for Engine Polygraph are the automakers themselves. Strock said they could use the technology to monitor powerplant variability during manufacturing. “That’s something that would be very valuable,” he said, reducing warranty costs. They could also put these in their maintenance facilities to gather even more data in order to keep tabs conditions that occur prior to an engine failure.

But to date, OEMs have had little interest in this technology. Strock said one person at an automaker even asked him, “Why would we want to know how many bad engines we let go?”

Still, they’re not done with car companies just yet. Further improving Engine Polygraph, they’re planning on adding a new diagnostic feature to the system that will help operators pinpoint specific technical issues. Essentially, it would spell out the condition an engine is in, as well as likely problems and possible fixes. Implementing this is a very high priority for them, something they’re going to do before going after the automakers again, though they do need additional funding before this becomes a reality.

Availability

Engine Polygraph has been commercially available for at least two years and is slowly gaining customers. Currently, “We are in discussions with several major prospects,” said Strock, including a national fleet-service chain and even a company based in Peru.

Two-channel kits are priced $5,000. As mentioned, they’ll simultaneously monitor a vehicle’s crankcase and exhaust. A $7,500 four-channel version is offered as well, which can also keep tabs on the ignition system and oil pump, though this capability hasn’t been fully utilized at this point.

Still, as they continue to refine and improve Engine Polygraph, it will likely expand its presence in the marketplace. “We are making… progress and getting more traction,” Strock said. So, perhaps the next time you take your vehicle in for service the technician will have gained superpowers, the ability to see deep inside its engine.